However, the recovery and separation of lactic acid from microbial fermentation media are relatively complicated and expensive, especially in the process relating to second-generation (2G) lactic acid recovery. Fermentation has been considered the preferred method for producing high-purity lactic acid in the industry over chemical synthesis. Its global market demand has significantly increased in recent years, with a CAGR of 18.7% from 2019 to 2025.

#LIQUID LIQUID EXTRACTION IN DOWNSTREAM PROCESSING FREE#

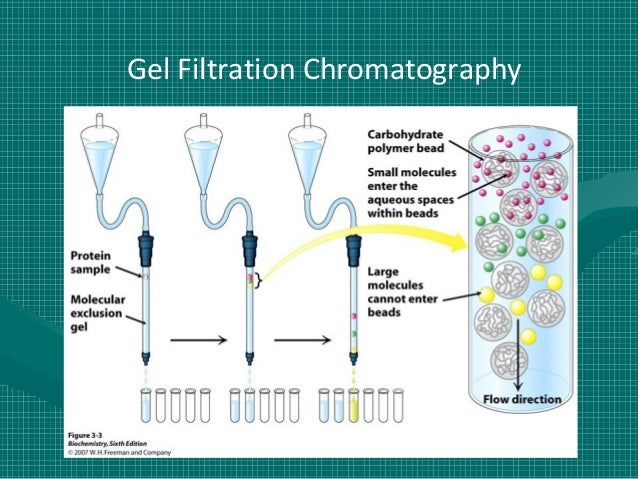

The eluate is free from emulsions and can be evaporated without further drying prior to further analysis.Lactic acid has become one of the most important chemical substances used in various sectors. During this process, the aqueous phase remains on the stationary phase. All lipophilic compounds are extracted from the aqueous into the organic phase. Subsequently, elution takes place using organic solvents that are non-miscible with water, such as diethyl ether, ethyl acetate or halogenated hydrocarbons. It distributes itself in the form of a thin film over the chemically-inert matrix, thus acting as a liquid stationary phase. The aqueous sample is applied onto the dry EXtrelut® NT sorbent. This guarantees that the indicated sample volume can be adsorbed. Furthermore, the quantity of the sorbent to be used is accurately calculated on the basis of the absorption capacity of the production batch.

However, thorough testing of the raw material and stringent control of the final product ensure its high quality remains uniform. Since it is a natural product, the appearance of the sorbent and its water absorption capacity can fluctuate. This kieselguhr matrix is chemically inert and can be used in the pH range of 1-13. High-Quality, Chemically-Inert MatrixĮXtrelut® NT columns use a wide-pore, highly pure diatomaceous earth-based solid phase. Liquid-liquid extractions can now be performed more efficiently, more simply and more effectively than ever before. This makes EXtrelut® NT columns also suitable for semi-automated procedures. Elution is quick and proceeds independently under hydrostatic pressure. Furthermore, the eluate need not be dried prior to evaporation. In contrast to the traditional technique, the columns enable quantitative extractions to be carried out in one step, thus drastically reducing solvent consumption and extraction time. Merck’s EXtrelut® NT columns avoid the challenges of liquid-liquid extraction because they replace the separation funnel. EXtrelut® NT20 for up to 20 ml of aqueous sample.EXtrelut® NT3 for up to 3 ml of aqueous sample.EXtrelut® NT1 for up to 1 ml of aqueous sample.

It is also a personnel-intense technique and cannot be effectively automated. However, this classical method presents certain disadvantages, such as the formation of emulsions, poor phase separation, and high solvent consumption due to repeated extraction cycles. For this purpose, liquid-liquid extraction with a separation funnel is frequently used to isolate target analytes from other matrix compounds. Sample preparation is essential for effective chromatographic analysis of lipophilic compounds in complex samples such as serum, urine or food. EXtrelut®: More Efficient, More Effective, Less Effort

0 kommentar(er)

0 kommentar(er)